News

What is TFT-LCD?

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

TFT: Thin-film transistor

LCD: Liquid crystal display (LCD)

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TRANSIST or-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

Three main stages of TFT LCD production process:

The first Array

- The Array process in the front segment is similar to the semiconductor process, except that thin-film transistors are made on glass rather than silicon wafers.

Midway through the Cell

- The middle Cell is based on the glass substrate of the front segment Array, which is combined with the glass substrate of the color filter, and liquid crystal (LC) is injected between the two glass substrates.

Module Assembly

-The rear module assembly process is the production operation of assembling the glass after the Cell process with other components such as backlight plate, circuit, frame, etc.

Latest technology development

Organic light-emitting display

Organic Light EmitTIng Display, or OLED, is a technology that has the following superior use characteristics.

—Spontaneous light

—Ultra-thin characteristics

—High brightness

—High luminous efficiency

—High contrast

—Microsecond reaction time

—Ultra-wide Angle of view

—Low power consumption

—Can use a wide range of temperature

—Flexible panel

—Low-temperature polysilicon

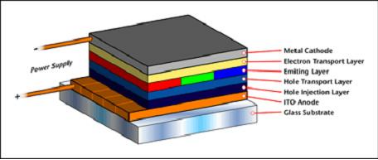

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

RELATED NEWS

- Difference Between Monitor and Television 2022-06-09

- WHICH TYPE OF TOUCH SCREEN IS BEST FOR YOU? 2018-08-01

- The Various Uses for UV Light 2022-10-07

- What are the differences among COG, FOG, COB, COF, TAB lcds? 2021-06-19

- What is the relationship between glass substrate size and generation? 2021-10-13

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lani. Zhang

Phone: 13713457217

E-mail: fasstlcd@hotmail.com

Whatsapp:13713457217

Add: No 6-608, B2 Building,Sanhe International,Tongsheng community,Dalang Row,Longhua district, Shenzhen,China